It has been a lot longer than I’d like since I last worked on the Production Studio. Unfortunately, Student Media had a lot of staff leave in the last year and a half and I had to pick up a lot of their responsibilities. Luckily, we hired two new full time staff members at the end of the Spring semester. Once they are up to speed, hopefully I can turn my attention back to neglected projects like the Production Studio.

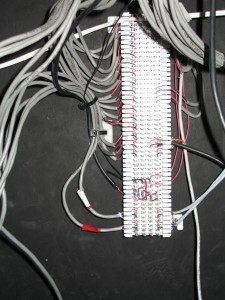

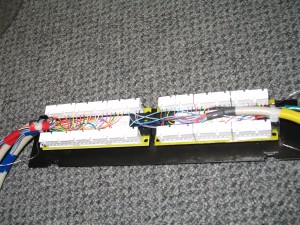

I made a lot of progress this week. I wired up an Ethernet patch panel to replace the 66 block we currently use. No, our new system isn’t IP-Audio based – it is a mix of analog and serial digital (AES/EBU, S/PDIF). I decided to use Ethernet since both parts and tools are plentiful and cheap. I could have used a 110 block instead of a patch panel, but there is a certain appeal to being able to change a connection down the road without a punchdown tool.

While we won’t need a punchdown tool in the future, I sure needed one this week while wiring up the patch panel. A spreadsheet we created to document the wiring takes two pages when printed out. The version of the Logitek AE-32 engine we has DB-25 outputs, so I had to wire four serial cables into the patch panel. Luckily, RS232 and Cat 5/6 use similar gauge wire (around 24 gauge).

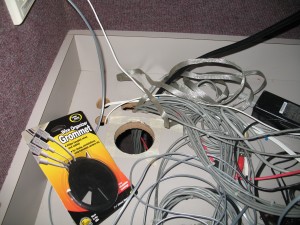

Since I split the equipment into two racks, I will have to pass a lot of cables through the table. The three small existing holes are not enough to accommodate all the cables. So, I drilled a new 3″ hole in the table. Unfortunately, the grommet I bought for the hole is 80mm, which is slightly larger than 3″ and I couldn’t get it to fit. Looks like I need to find a file.

Another reason I will need more space for cables is that most of the equipment was plugged into the nearest power outlet, often without a surge protector. I think this contributed to the ground loop hum problem in the studio. I plan to plug all the equipment into our Furman PL-8c power conditioner, which means I have to route all the power cables to one location.

Next, I will have to fabricate wires between the patch panel and the equipment. That’s a lot of soldering that will probably take several days to complete. Hopefully, WGMU won’t have to wait another 8 months until I have free time in my schedule.