The carpet in our office always appears dirty. Plus, no one has witnessed Housekeeping vacuuming our offices. So how dirty is our office anyway? I do a little experiment to find out.

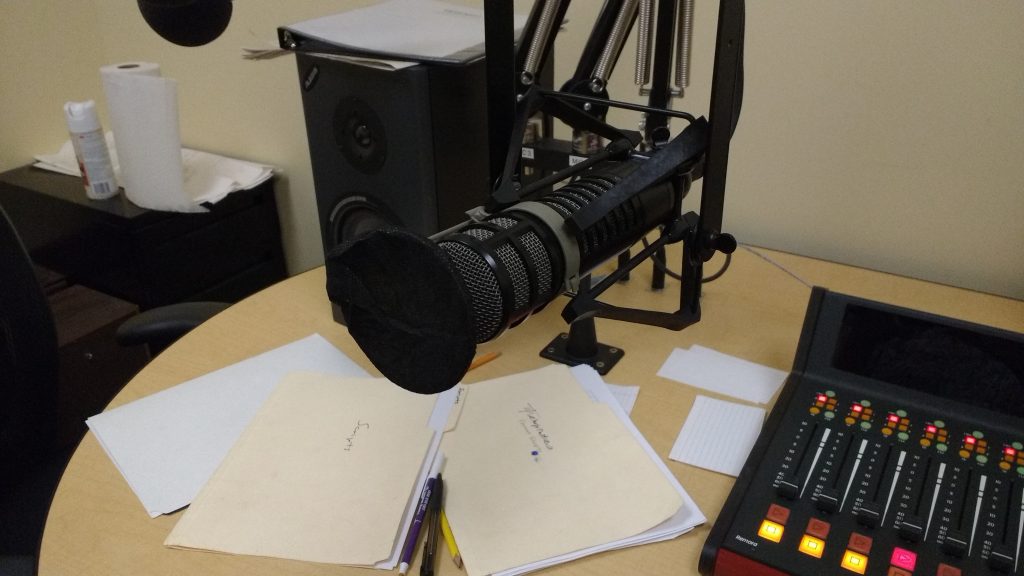

Temporary Radio Studio for WGMU Summer Camp

For most of the past 25 years (last year was an exception for obvious reasons), WGMU, our radio station, has run a summer camp for middle and high school students.

Even though Coronavirus seems to be diminishing in the United States (knock on wood), our University still has restrictions in place for summer camps since the majority of people under 18 are not vaccinated.

One of the restrictions in place is social distancing. Given the small size of our three radio studios, we can only fit two campers per studio, for a total of six campers.

Unfortunately, that is a big problem since the radio station relies on the revenue from the camp to sustain their operations. And we can’t absorb less revenue given the massive hits our budget has taken. Once again, we had to get creative.

The solution:

I set up a temporary radio studio in our conference room using equipment we use for remotes, equipment from the TV station and equipment from our “graveyard”.

The graveyard is where I keep older, but still functional, equipment in case I have to replace newer equipment that fails. Occasionally, the equipment gets a second lease on life if I can find a new use for it. I pull equipment from the graveyard all the time. Good thing I’m a hoarder!

The equipment:

- 1x Sennheiser MD 421 on the beige OC White Mic arm.

- 2x Shure SM58 on the black MXL arms.

- 1x Yamaha MG102C Mixer

- 1x Rolls RA53b Headphone Amplifier

- 1x Logitech X140 Speakers

- 1x Dell Latitude E6430 Laptop

The Yamaha mixer is part of our remote setup. The Shure SM58’s and laptop are from the TV station. Everything else is from the graveyard.

2020-2021 Sports Broadcasting Year in Review

I am continuing our yearly tradition of looking back at what happened during the academic year. And it was quite the year, for many reasons.

If you are wondering why I’m writing this review instead of Zach Hamilton, it is because he graduated and now has a full-time job at NBC Sports Washington (just like Tyler, although they’re in different departments).

The year started quietly, with no sports in the Fall semester due to the COVID-19 pandemic. Then we received word that we would be returning to action, broadcasting both the Fall and Spring sports during the Spring semester, with Wrestling thrown on top for good measure. At one point, we were looking at over 90 broadcasts.

Ultimately, we did 75 broadcasts this year. The schedule was constantly in flux due to COVID-19 “pauses” where teams were unable to complete due to positive cases somewhere within their programs. Additionally, we saw a very cold February where we were unable to do any outdoor sports until near the end of the month (Women’s Soccer vs. Georgetown on February 25). Even then, we still completed more broadcasts this year compared to last.

We worked as hard as we could to keep our crew safe with masks, gloves and as much social distancing as we could manage in the cramped press boxes. To aid with social distancing, we had to find a way to have less people working inside the press box. In the end, we figured a way that the color commentator and replay operator could work remotely. This impressed several people, with our counterparts at George Washington University calling us and asking us how we pulled it off.

Remote Commentator during Softball vs. St Bonaventure on March 14, 2021. Left: Valerie Preactor. Right: Brian McSweeney.

Sometimes people would work from home, sometimes they would work out of our office in The Hub. Since our video studio in The Hub wasn’t used by Mason Cable Network this year (MCN produced all of their shows remotely), we reconfigured it for color commentators. Future site of half-time shows …?

I am grateful that we managed to complete the year without any COVID-19 pauses of our own.

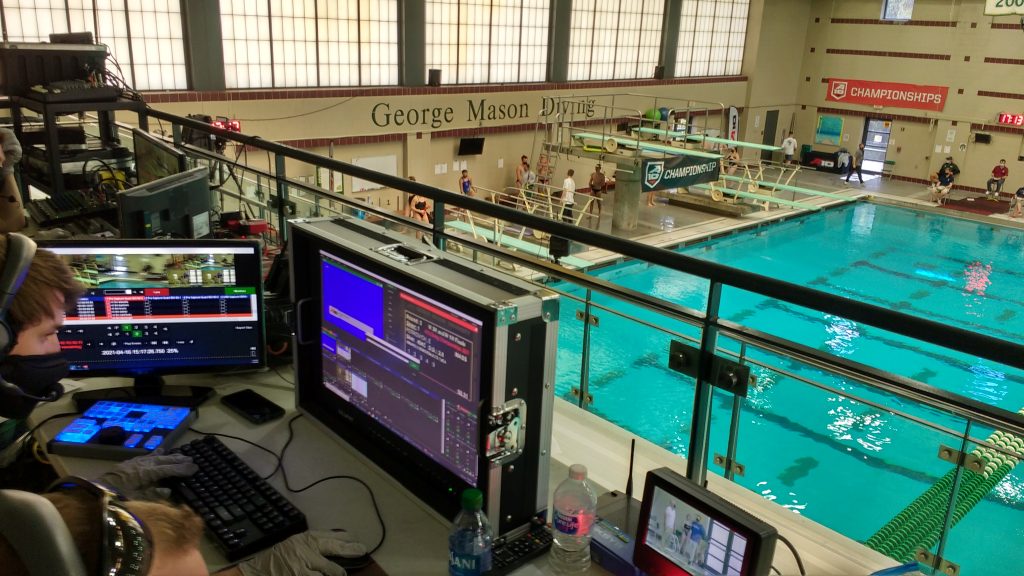

We also got the opportunity to try our hand at a couple of new sports. Up first was the A-10 Diving Championships on April 15 and 16. For some reason, the A-10 decided to separate swimming and diving at the last minute. The swimming events continued as planned at Spire Institute in Geneva, Ohio, but the diving events came to George Mason. This was our first ever broadcast from the Aquatic and Fitness Center, and I think we did a great job considering the short turnaround. I have to say that the pace of dives was a lot quicker than we expected.

Next up was the A-10 Outdoor Track and Field Championships on May 1 and 2. Technically, this was the second track broadcast we did, with the first being in April 2018, which we did as part of Trent Lancaster’s senior project. Speaking of Trent Lancaster, he came back to help us with these broadcasts. Good thing too, since this was easily the most complex broadcasts we ever did.

Compared with our first broadcast, we covered every single track event and added all the field events. This included the throwing field events across the street. It took pretty much every single piece of equipment we had to pull this off. It was so complex, that Zach Hamilton, Collin Teslez, Cruz Sanchez and myself had to go over a day earlier to run all the cabling.

A-10 Outdoor Track and Field Championships May 2, 2021. From left to right, Zach Hamilton, Jordan Jacobsen, David Carroll, Josh Yourish and Trent Lancaster.

We finally added a remote-controlled “PTZ” outfield cam at Spuhler Field. After years of effort, we finally got it and it’s great! Not only is the quality better, but I don’t have to climb a ladder every game to mount a camera anymore. For some reason, I didn’t take a picture of the PTZ installed, but here’s a picture of the camera after I assembled and tested it. Thanks to everyone who made it happen, including Jay Marsh and Jeff O’Bier.

The “Iron Man” of the year is Oscar Avelar, who did 39 broadcasts. Oscar also stepped in as broadcast director one particularly busy weekend when Zach, Collin and I were tied up. Honorary mention goes to Long Tran who did two less broadcasts than Oscar, but actually clocked more hours thanks to a lot of lengthy baseball broadcasts.

Congratulations to our graduating seniors Oscar Avelar, Jon Linney, Valerie Preactor and Collin Telesz. Collin will return as graduate student however.

Enabling Student Media in a Time of Shutdowns and Social Distancing

During the Summer, we had lots of discussions internally about how student media could continue without our students having access to the spaces and equipment that they use on a daily basis. It took some serious effort, but we devised ways to continue operations in spite of the challenges posed by building closures, social distancing requirements and massive hits to our budget.

I’m very proud of how we managed to substantially transform our operations. It is a testament to the flexibility and ingenuity of both professional staff and students. Unfortunately, this amazing achievement has gone unnoticed by our administration and others.

I am going to share some of the details on what we did.

I first began looking into ways of increasing remote work after suffering a health scare in July 2019 . That way I could continue working if my health deteriorated further. I worked with our central IT department to set up VPN (Virtual Private Network), a way to access our internal network from home. VPN has been the linchpin to everything we have done. A silver lining to spending a day in the emergency room and nearly a month off of work.

Mason Cable Network, our television station, started producing 100% remote shows in September. To date, we have produced a dozen remote shows. Most of the shows are produced using vMix’s Call functionality. From a user’s perspective, vMix Call is identical to other video conferencing services like Zoom or WebEx. You just visit a website with a device with a camera (i.e., laptop with webcam, smart phone).

However, the difference is vMix allows you to have all the features of a audio/video mixer, including switching among camera angles, inserting graphic overlays, manually adjusting audio levels, etc. In other words, you can have a full-fledged television show versus the standard grid you get with video conferencing services.

Luckily for us, we already owned vMix. We originally purchased it for instant replay purposes for the sports broadcasts we do for ESPN+. Since Fall sports were postponed, we were able to redeploy vMix for remote broadcasts. The computer with vMix has remained in our office and the technical director connects to it using VPN and VNC (Virtual Network Computing), a way of sharing the desktop of a machine over a network.

We use Zoom as an IFB (Interruptible foldback) to cue talent and general communication purposes.

For WGMU, our radio station, we also use VPN and VNC to control our computer-based radio automation system and upload new songs. Using a radio automation system is nothing new for us – we’ve been using one for years.

However, our workflow primarily revolves around having a DJ in the studio working the console and speaking into a mic.

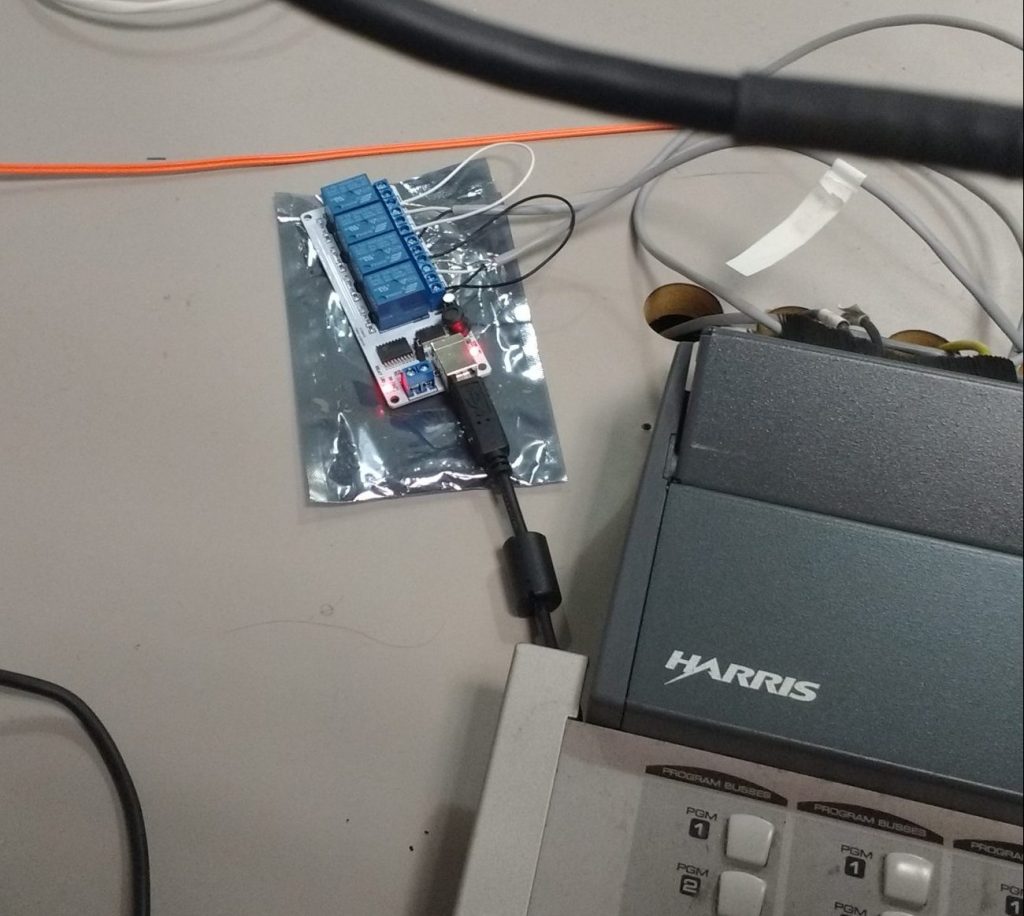

To enable a 100% remote workflow, I purchased a $23 USB controlled relay off of Amazon and jerry-rigged a way to toggle inputs on the console on and off using the same computer the radio automation software is on.

USB relay used to remotely turn inputs on our radio console on and off. I’ll permanently mount it when I have a spare moment – which means in a year or two.

Theoretically, a DJ could send audio to the Comrex Access unit in our studio, use the USB relay to control the board remotely and VPN/VNC to control the radio automation software. Normally, we use a portable Comrex Access unit during basketball games to send game audio to the rackmount Comrex Access in our studio. However, the Comrex Access supports a SIP mode, which means we don’t need specialized hardware or software and can use any off-the-shelf VOIP (Voice over IP) software. Comrex (and I) recommend Linphone, a free VOIP software. By using freely available software, we don’t have to worry about each DJ having expensive equipment.

Unfortunately, I say “theoretically” since no DJ has taken us up on the offer to do a completely remote show. Still, we have used the system I jerry-rigged to reset everything after a power outage or a session with a particularly novice DJ.

Since all DJs are currently doing in-person shows, we had to invest in ways to keep them safe. Unfortunately, this has been extremely labor intensive as we have to clean the studios between each show. To manage the increased workload, we’ve had to limit studio sessions to two days a week. We also have to let the studios air out between shows as well (initially one hour, which we later reduced to 30 minutes due to demand). Everyone has to wear gloves and we put disposable mic covers on the pop filters. I wanted to purchase air purifiers for all the studios, but our University’s Environmental Health and Safety Office rejected that as “unnecessary”, even though research has shown Coronavirus is primarily transmitted through droplets in the air and DJ’s are doing shows without masks (albeit alone).

Our literary journals long ago switched to a mostly remote workflow, so they have been the least affected by Coronavirus-related precautions. Most of our journals use Submittable to accept and manage submissions. Ironically, Phoebe, our oldest literary journal, just launched the Incarcerated Writers Project, which solicits writings from people in prisons and all submissions are mailed in.

Probably the hardest hit of all of our groups has been Fourth Estate, our newspaper. While they continue to regularly post things on their website, they ceased printing a newspaper for financial and logistical reasons. We rely on advertising to support printing our paper and newspaper advertising has all but disappeared. Historically, we have distributed newspaper in racks placed around campus. Who is going to pick up papers out of the racks when the dorms are less than half full and most students are not coming to campus since their classes are online?

I have a feeling that we may never resume printing a paper, which bums me out.

To end on a happy note, I’m proud that GMU Student Media has enabled our students to exercise their first amendment rights in spite of everything going on right now. It certainly hasn’t been easy.

Why a budget cut will devastate Student Media

In a time where Coronavirus-related measures have resulted in the largest percentage of people unemployed since the Great Recession, and it’s resultant negative impact on tax revenues, I’m making the argument that George Mason University Student Media’s budget should not be cut.

Why?

The short answer is that any significant cut to our budget will significantly, and most likely permanently, reduce student opportunities to express themselves. Given how small our budget is currently and how important our role is to the protection and exercise of students’ First Amendment rights, the University should make every effort to maintain our budget.

Our budget is a tiny fraction (0.046%) of the University’s $1.25 billion overall budget. Our actual cost to the University is actually less since 13.4% of our revenue is self-generated through activities like advertising and services.

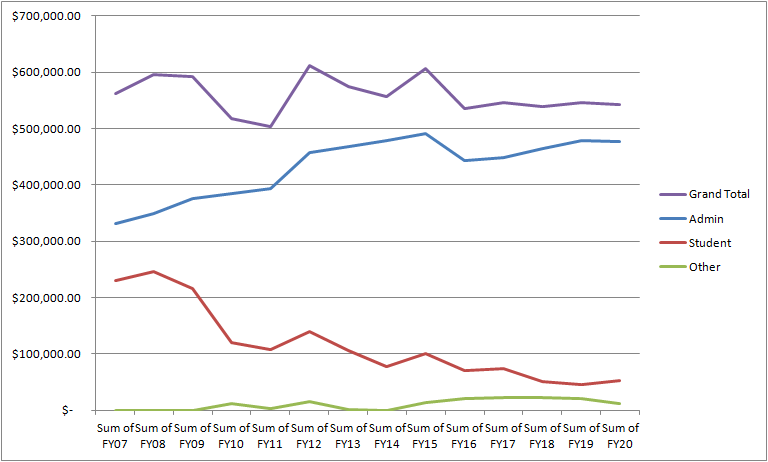

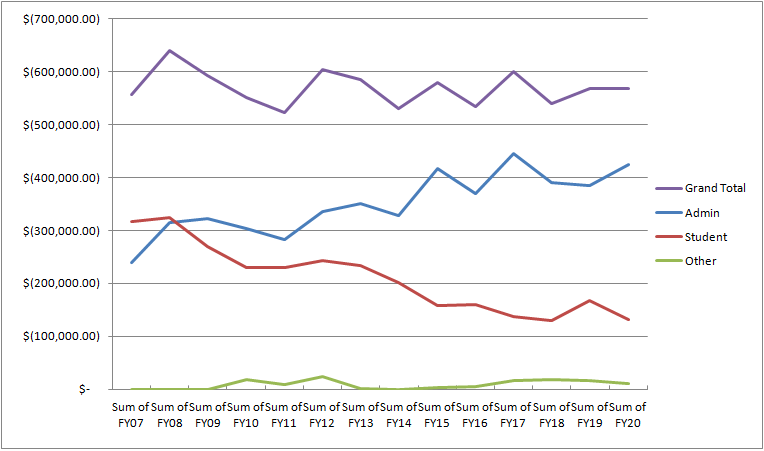

Looking at our revenue over the past fourteen years (Figure 1 below), our overall revenue is lower now than it was fourteen years ago. Think of how many things have gone up in price since 2007. Wages have gone up. For example, the Federal Minimum Wage went up to $7.25/hr in 2009. And it’s going up to $9.50/hr in Virginia next year. Printing costs have gone up. Web hosting costs have gone up.

It’s also important to look up what makes up revenue. The biggest part of our revenue is the student fee transfer. The second biggest part is self generated revenue. As I mentioned above, self generated revenue is things like newspaper advertising, production services, journal submission fees and subscriptions. Unfortunately, since the Great Recession of 2007 – 2009, self generated revenue has been consistently trending downward. See the red line (third from the top) in Figure 1.

I’ve heard some administrators say that if Student Media needs more money, they should make more self generated revenue. This is pretty much out of our control. Unless you are Google, pretty much no one is making as much in advertising as they used to. I’d like to see those same administrators buck macro-economic trends. If you need more graduate students …

To be fair, the University was initially willing to invest in Student Media. However, there was a change in administration and the new regime took a hatchet to our student fee revenue, cutting it back to pre-2012 levels.

You can see the results of what I call the double-whammy, the student fee cuts and decline in advertising sales, in Figure 3 below.

In those fourteen years, we’ve cut the number of copies of the newspaper we print by a third and the number of literary journals we print by over 50%. Entire groups have disappeared, including Connect2Mason, an award-winning news website, and GMView, the yearbook (although lack of participation played a bigger role in killing the yearbook).

You might notice that the “Admin” line has grown. At first blush this may appear to be “administrative bloat“, but it’s not. First, the only part of our budget that has grown is professional staff salary, and only because it is mandated by the Commonwealth of Virginia as a “cost of living adjustment” (remember things cost more than fourteen years ago). Second, a lot of functions were centralized in an attempt to boost efficiency – functions like the advertising sales staff, web hosting and publication distribution.

Also, the University brought in high-priced consultants to look at staffing levels. They looked at the number of students we serve and what our peers spend on student media and concluded that we needed to be doubled in size immediately. Of course, no action was taken on that particular recommendation.

This shrinking of the amount we spend on student is something that bothers me greatly. We need to serve the students. It’s right there in the name, Student Media.

Any budget cuts fall disproportionately on the students since professional staff costs are essentially fixed.

At this point, after absorbing over a decade’s worth of cuts, there’s no more fat left to cut. If you’re only printing a few hundred copies of a journal, how much more can you cut before you have nothing? The most likely outcome of significant cuts is our smaller groups that have little to no self-generated revenue ceasing to exist, groups like Hispanic Culture Review, a Spanish-English journal covering Hispanic culture, and So to Speak, a journal covering feminist topics.

I would hate to stop supporting diverse voices, at a time where we need it more than ever.

I would hope that the University would find a few dollars (our budget is 0.046% remember, relative pocket change) somewhere to spare us deep cuts.

Unfortunately, it’s probably naive of me to thing that our University will suddenly start supporting us considering they didn’t when times where better. George Mason University record in protecting first amendment rights like freedom of the press or freedom of speech has not been spotless either.

WordPress Plugins: Too Much of a Good Thing?

I’ve been very busy lately, which is why it has been some time since I’ve last posted anything. One area of my job that sucks a lot of time is maintaining onMason, the WordPress-based platform on which this blog runs.

onMason recently celebrated it’s tenth anniversary, which means onMason is very, very old in tech years.

One of the things I’ve been trying to do is update the PHP, the programming language WordPress is written in, to version 7.3. WordPress itself is ready for this upgrade. In fact, they display a very misleading “PHP Update is Required” warning in the Dashboard if you are running anything but PHP 7.3.

However, many of the plugins (and themes) we use on the site will not run or run poorly with PHP 7.3. For example, the report generated by the PHP Compatibility Checker plugin is an imposing 161 pages long.

So why is upgrading such an ordeal? It’s because of a mistake we made when we created onMason back in 2009 – we decided that we would basically install any plugins (or themes) our users asked for. Over the next ten years, we installed no less than 160 plugins. We were even less selective with themes, with nearly 200 installed over the same period. So what’s the problem with that? After all, plugins (and themes) add functionality not included with WordPress and who doesn’t want more features?

The problem is that plugins are not maintained as well as the WordPress core, typically only for a few years. Sometimes the author loses interest in the plugin, or sometimes they tragically pass away. Unfortunately, it just isn’t in the WordPress community’s DNA to adopt an abandoned plugin, no matter how popular it once was. It is also rare that a plugin will import another plugin’s data and settings. Occasionally, a plugin won’t even import data and settings from an older version of itself.

Over the years, I’ve managed to slim down the number of the number of plugins and themes to around 80 and 130 respectively. If I’m lucky, the plugin functionality gets integrated into the WordPress core and I no longer need the plugin. Sometimes the plugin relied on a web service that shut down (e.g., del.icio.us). But most of the time, I effectively become the maintainer for dozens of abandoned plugins and themes.

Is it worth it to maintain a plugin for one or two users? Is it worth it to have plugins to support features that have fallen out of favor (like tag clouds)? Is it worth it to support advanced features (like podcasts) when many users may want to use it, but probably never will?

For years, I’ve known how many sites use each plugin. However, what I didn’t know was how many people actually used the plugin. It was shocking to learn that around 70-80% of people who activate a plugin, never actually use it. I can tell since many plugins require users to configure something – completing a wizard, entering an API key, etc. If these steps were never completed, the plugin was obviously never used. In one example (Smart YouTube Pro), a plugin was active on 30 sites, but not a single user actually used it.

Due to health reasons, I no longer have the time to maintain all these abandoned plugins and themes. I’ve come to the bitter conclusion that it’s best to run as close to a stock WordPress instance as possible. It’s the only way we can maintain a secure and high performing service with the resources we currently have. So, in the future, you’ll see a lot less options for additional plugins and themes – and that is a good thing.

Progress

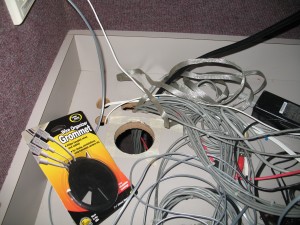

It may not look like much, but that box full of cables represents several days worth of work.

Unfortunately, the necessary cables never come in the box when it comes to pro-grade audio equipment – you have to make them yourself.

Part of the problem is that there are so many different types of connectors for audio equipments, including XLR, RCA, 1/4″ phone, 3.5mm mini-jack, etc – the list goes on. Also, every studio is different, so you never know what length you’re going to need. For our Logitek AE-32 Audio Engine, I had to create cables that go from DB25 to XLR, RCA or terminal block with lengths ranging from 6 feet to 18 feet.

It takes time to measure, cut, solder, test and label* each wire. A couple of things slowed me down.

First, I don’t have a dedicated workbench so I have to set up everything each time I work. After hauling out all my tools and warming up the soldering gun, 30 minutes pass without actually accomplishing any real work.

Second, I use lead-free solder that has a melting point of 422.6 degrees Fahrenheit, which is a good 50 degrees higher than 60/40 tin/lead solder. That makes it more difficult to work with since you have to wait longer for everything to heat up (unless you like cold-solder joints). Of course, you’ll become infertile after being exposed to lead, so lead-free solder does have some benefits.

These factors combine to make it necessary to have a full hour of uninterrupted work time in order for me to complete anything. Unfortunately, I rarely have an hour when I’m not interrupted so needless to say, the Production Studio upgrade has gone very slowly.

* It is important to label each wire. It may not seem important at first, and if you never ever repair, replace or add any equipment to your studio (yeah, right), you might be able to get away with it. However, without labels and documentation, repairs, upgrades and additions become very difficult – tracing connections is no fun. I guarantee, you will not remember how you hooked things up a year from now and it may not even be you who does the repair, upgrade or addition.

Rise of the Machines

Our DVD duplication “factory” – an Epson Discproducer PP-50 with a Dell Ultra Small Form Factor computer.

It’s no secret that “traditional” college media, like newspapers and yearbooks, are struggling financially these days. Our yearbook, GM View, is no different. It happened slowly, but our yearbook sales have eroded to the point that producing a yearbook is becoming a serious financial burden.

Honestly, I’ve never understood why our yearbook doesn’t sell better. It’s a great way to remember one’s time at Mason, doesn’t cost a lot (at less than $50) and even comes with a companion DVD. I can only guess that most students aren’t aware that we have a yearbook.

Several other universities have discontinued their yearbooks because of rising costs and sagging sales, but I didn’t want the same fate for our yearbook since it is one of the few student publications, along with Broadside and Phoebe, that existed before George Mason University became an independent university in 1972. After all these years, not having a yearbook just seems wrong.

Since I have limited control over marketing, I focused on the areas where I could make a difference – technology.

One of the areas I quickly identified was the cost of DVD duplication. In previous years, we contracted out duplication, paying around $2.50 per DVD. Additionally, we were spending $1.24 for packaging on top of that. Nearly $4 per DVD seemed expensive to me. And I’m not even including shipping costs or the cost of the labor it took to assemble everything when it came in.

We had tried DVD duplication in-house before. Gunston Hall asked us for 125 copies of our George Mason documentary (a CBI 2014 finalist for Best Documentary) on DVD. We were unable to contract this job out because of the tight turn-around time. So, I set up 10 laptop computers and, with the assistance of our front desk staff, began burning DVDs. We printed labels out on stickers and applied them to the DVDs. It took us two very labor-intensive days to finish the job and the results were so-so. This is clearly not the way to go.

After that, I started looking into purchasing a DVD duplicating machine. They aren’t terribly expensive and they eliminate virtually all the labor necessary in creating a DVD. No need to load each disc or apply stickers. After some research, we ended up purchasing an Epson Discproducer PP-50 for a little more than $1,800.

For the 2013-2014 GM View yearbook, we also made a change in packaging. In previous years, we shipped the DVD in a separate keep case. In my opinion, this made it seem like the DVD was a separate product instead of a companion to the yearbook. This year, we included the DVD in a sleeve on the inside front cover of the yearbook. Not only does this make the DVD truly a part of the yearbook, it saves us quite a bit in packaging cost, and is lighter and cheaper to ship to boot.

Bottom line, the yearbook DVD, including packaging, now costs around $1.25. With a savings of around $2.50 per DVD, we should have the machine paid off in two to three years, assuming we don’t take any other duplicating jobs (which I’d very much like to do). And the results look great. I feel that we have cut costs without sacrificing quality.

Hopefully, with the other changes we made, including opening the yearbook up to all students (not just seniors) and accepting orders online, GM view will be around for years to come.

Here’s a video of the Epson Discproducer PP-50 at work:

Convergence Area

This really isn’t a post about technology. However, if you’ve read some of my previous posts, you might notice that I pay attention to how people interact the equipment and their workspaces.

During 2008-2010, when my Director, Kathryn Mangus, and I were planning our space in The Hub (back then SUB 2), we both whole-heartedly agreed on the need for the Student Media groups to “converge.” More than simply sharing the same office suite, we wanted each of the groups to constantly work together and build on each other’s strengths.

For example, the newspaper could work with the radio station and cable television station on news shows. This didn’t mean that the newspaper would simply produce shows that would air on the stations, but rather the newspaper would provide the reporting expertise and the radio and television stations would provide the audio and video expertise (respectively). It would truly be a joint production.

To create a space to support this ideal, we planned to have the newspaper, radio station and cable television station surround a “convergence” area in the middle of the office. Each group would have their own space, but they could meet in the middle (literally and figuratively) to collaborate.

When we finally moved into our new space in February of 2011, we were shocked to find that our collaboration area consisted of a series of small cubicles. I think the designers were going for some sort of open plan office space, but it really didn’t meet our needs. I don’t see how you’re going to foster conversation by placing people in cramped and awkward cubicles, instead of, say, meeting tables. What is even more baffling is that we even discussed putting meeting tables in that space. Something definitely got lost in the translation.

Unfortunately, there was anything we could do to fix the problem at the time since there wasn’t any money left – there wasn’t even enough money to finish furnishing all of the offices.

Over the last couple of years, we tried to use the space for a variety on things like overflow space for newspaper editors and radio camp. However, nothing really worked out (it’s too small) and it seemed like wasted space.

Luckily, at the end of last fiscal year, we had a little bit of money left – enough money to buy some meeting tables to replace the cubicles.

I decided to pull apart the cubicles myself to save money. I’ve done it before – it’s really not that difficult. The cubicles are modular and come apart with a minimum of tools. All you really need are a pair of pliers, a rubber hammer and a screwdriver. I managed to do everything in around 8 hours. The most time-consuming part was re-routing all the network cables though the furniture.

While convergence is still a work in progress, we finally have a space that matches our initial vision.

Production Studio Upgrade – Patch Panel

It has been a lot longer than I’d like since I last worked on the Production Studio. Unfortunately, Student Media had a lot of staff leave in the last year and a half and I had to pick up a lot of their responsibilities. Luckily, we hired two new full time staff members at the end of the Spring semester. Once they are up to speed, hopefully I can turn my attention back to neglected projects like the Production Studio.

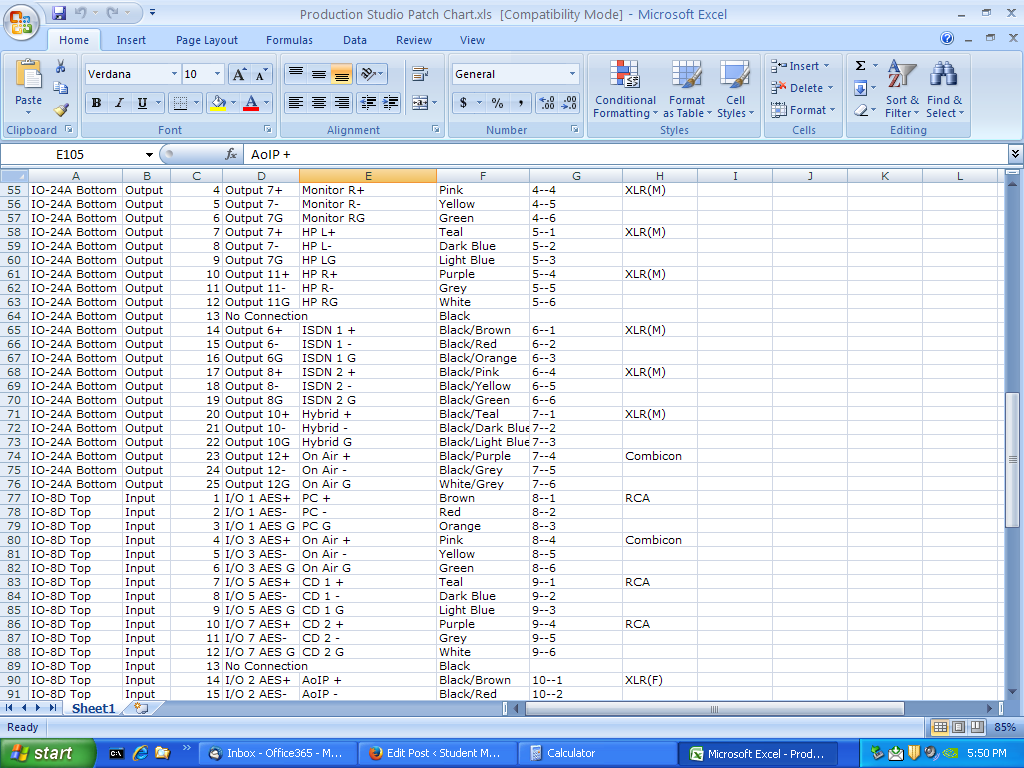

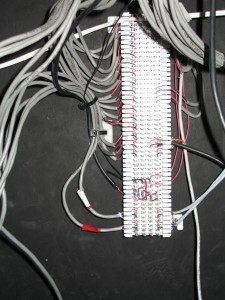

I made a lot of progress this week. I wired up an Ethernet patch panel to replace the 66 block we currently use. No, our new system isn’t IP-Audio based – it is a mix of analog and serial digital (AES/EBU, S/PDIF). I decided to use Ethernet since both parts and tools are plentiful and cheap. I could have used a 110 block instead of a patch panel, but there is a certain appeal to being able to change a connection down the road without a punchdown tool.

While we won’t need a punchdown tool in the future, I sure needed one this week while wiring up the patch panel. A spreadsheet we created to document the wiring takes two pages when printed out. The version of the Logitek AE-32 engine we has DB-25 outputs, so I had to wire four serial cables into the patch panel. Luckily, RS232 and Cat 5/6 use similar gauge wire (around 24 gauge).

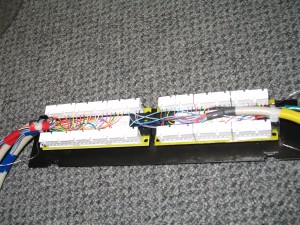

Since I split the equipment into two racks, I will have to pass a lot of cables through the table. The three small existing holes are not enough to accommodate all the cables. So, I drilled a new 3″ hole in the table. Unfortunately, the grommet I bought for the hole is 80mm, which is slightly larger than 3″ and I couldn’t get it to fit. Looks like I need to find a file.

Another reason I will need more space for cables is that most of the equipment was plugged into the nearest power outlet, often without a surge protector. I think this contributed to the ground loop hum problem in the studio. I plan to plug all the equipment into our Furman PL-8c power conditioner, which means I have to route all the power cables to one location.

Next, I will have to fabricate wires between the patch panel and the equipment. That’s a lot of soldering that will probably take several days to complete. Hopefully, WGMU won’t have to wait another 8 months until I have free time in my schedule.